NASA technology will ensure imperfect fruit in Thabeban, Bundaberg, now has a use.

SSS Strawberries officially opened its 4000-square metre factory in December to produce freeze dried and frozen fruit products under its own retail brand, Gina’s Table.

Gina’s Table general manager Gina Dang said once fully operational, the business would employ 50 staff.

She said she saw this as a natural evolution of the family’s business.

“We have been strawberry growers since arriving in Australia from Vietnam so know first-hand the back-breaking work it takes to get a good crop up and out of the ground,“ she said.

“The level of innovation now available in freeze dry technology will allow us to take the next step in value adding to tonnes of strawberries that may have ended up rejected and destroyed in the past due to market conditions.

“We invested in this factory as we saw a growing need to end food waste. It’s heartbreaking to watch fruit that we have grown get rejected and destroyed.

“We wanted to find a way to ensure that the fruit that can’t be sold due to strict criteria has a second life,” she said.

“Why should all that flavour go to waste?

“We give fruit that can’t be sold a second chance through freeze dry technology.

“This is the same technology that has helped food survive in space and we are going to be able to process (more than) 2000 tonnes of fruit at capacity.“

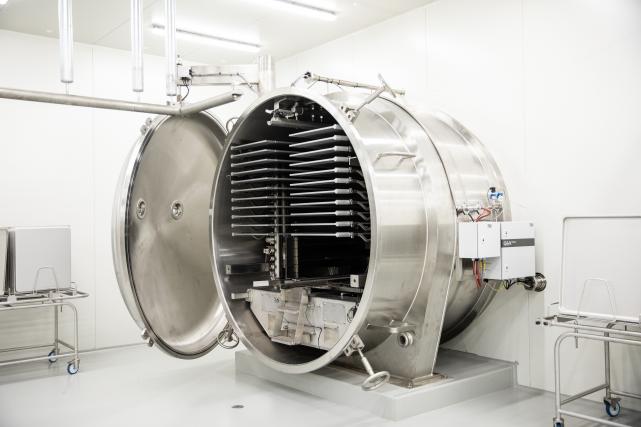

Freeze drying involves placing frozen raw materials in a refrigerated vacuum. Ice crystals in the product are then sublimated into water vapour, while the cell structure of the original product remains.

“This freeze drying machine from Denmark gives us many applications for food production such as frozen fruit, fruit purees, juices, dairy blends, powders, crumbles and pro-biotic yoghurts,“ Ms Dang said.

“It also helps growers like ourselves to create new and interesting product lines for both the Australian market and export markets.

“Freeze dried fruits retain their shape integrity, are light weight, have a long shelf life, are GMO free and all natural and, most importantly, it not only keeps but intensifies the flavour.“

SSS Strawberries stands for Seven Successful Siblings and is a family business that moved to Bundaberg more than 20 years ago.

“All my brothers and sisters Victor, Lily, Cindy, Tam, Trinity and Rena have worked incredibly hard to make this factory the logical next step in our family business,” she said.

“The seeds we are putting down today in opening this factory, plant the future – not only for our business but many others growers in Australia.”

Bundaberg region Mayor Jack Dempsey welcomed the investment made by SSS Strawberries which, he said, highlighted the region’s superior soils.

“The global food supply stemming from the Bundaberg region’s ‘food bowl’ perfectly combines our natural competitive advantage with state-of-the-art processing,” Mayor Dempsey said.

“The agricultural industry is a key contributor to our local economy and to have businesses not just growing but also processing and packing product in our region creates a substantial flow on effect.

“The Bundaberg name is known throughout the world as a supplier of high quality fresh produce and innovative products and this endeavour will further enhance that reputation.”

Fast Facts

* Factory site: 4000 square metres.

* Capacity to process 2000 tonnes of food per year.

* Locally grown fruit will be washed, frozen and freeze-dried, packaged and shipped, all from in-house.